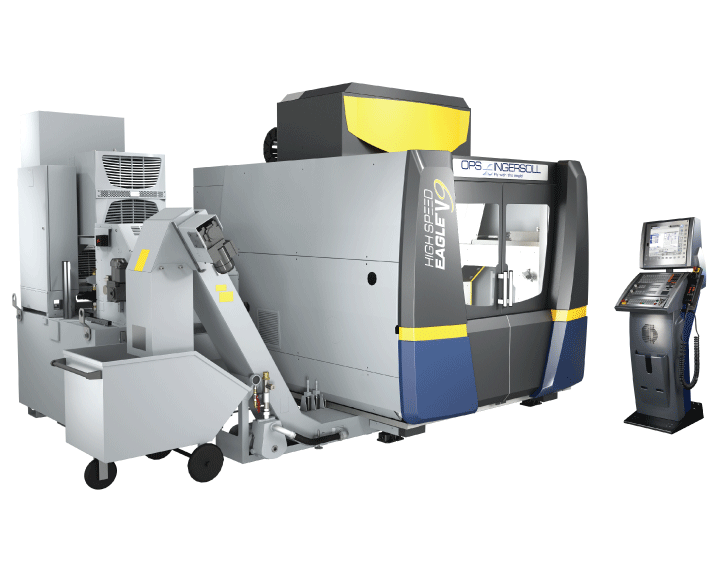

EAGLE V9C (5-AXIS WITH COOLANT SYSTEM)

Overview

A flexible, automation-ready, 5-axis machining solution for ultra precision machining with a coolant system.

The Eagle V9C (5-axis) is an ultra precision machining center with coolant system. The V9C is designed to be an ultra-rigid 5-axis vertical machining center with the capacity to handle a 1,100-pound workpiece on a 23.6” table surface. The Heidenhain TNC-640 control unit is mounted on a moveable pedestal for optimal positioning convenience. The Eagle V9C is designed with a side opening in the casting to allow robot loading from the right side with pallets up to 19.7” square.

If you’re looking for a robust, powerful tool that’s easy to access, operate, and fine-tune, all so you can better deliver top-tier products quickly and cost-effectively, then we have good news. The Eagle V9C might just be the flexible, functional 5-axis milling machine with temperature controlled coolant system for you.